Science

The simple appearance of a light sensor conceals the rigorous design behind each instrument. From the shape of the crown to the optical filter glass, every aspect of a light sensor is the result of scientific inquiry. For you, this means a dependable instrument that provides consistent top-of-the-line performance.

LI-COR brings over 40 years of experience designing and manufacturing light sensors, with over 150,000 units sold.

Sensor Design

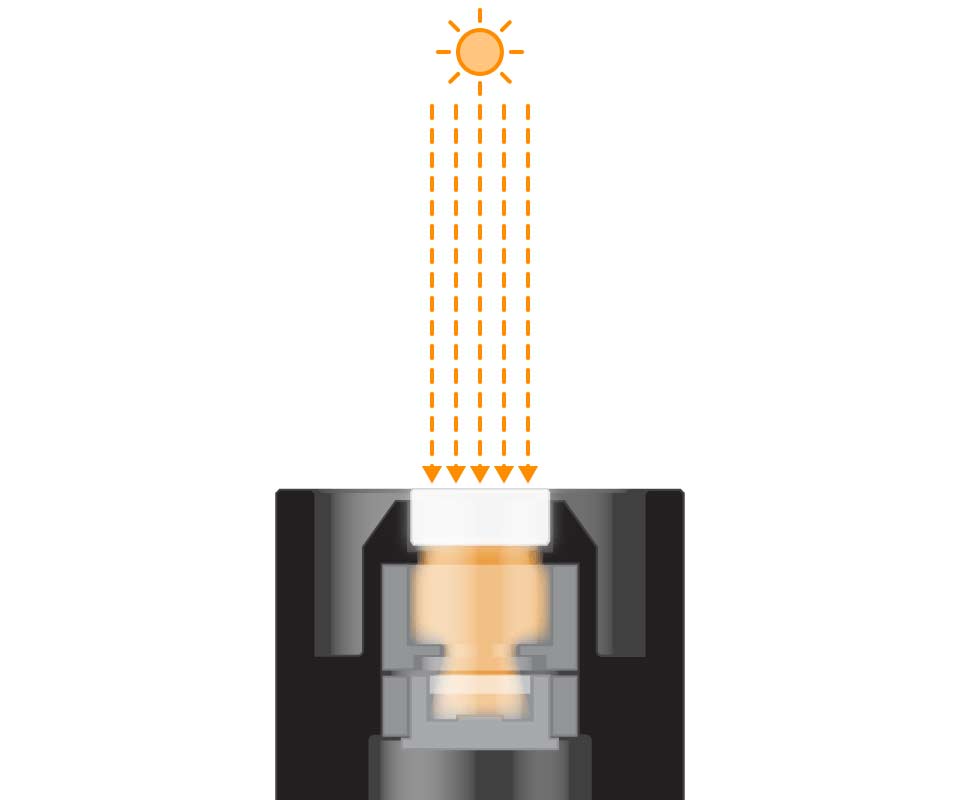

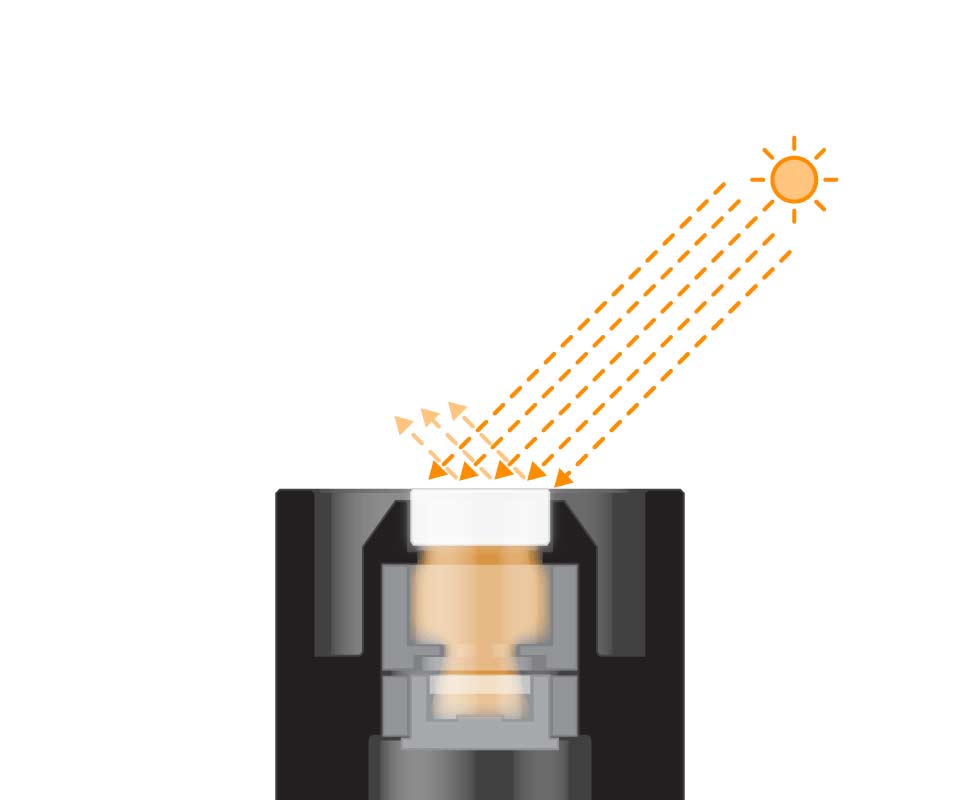

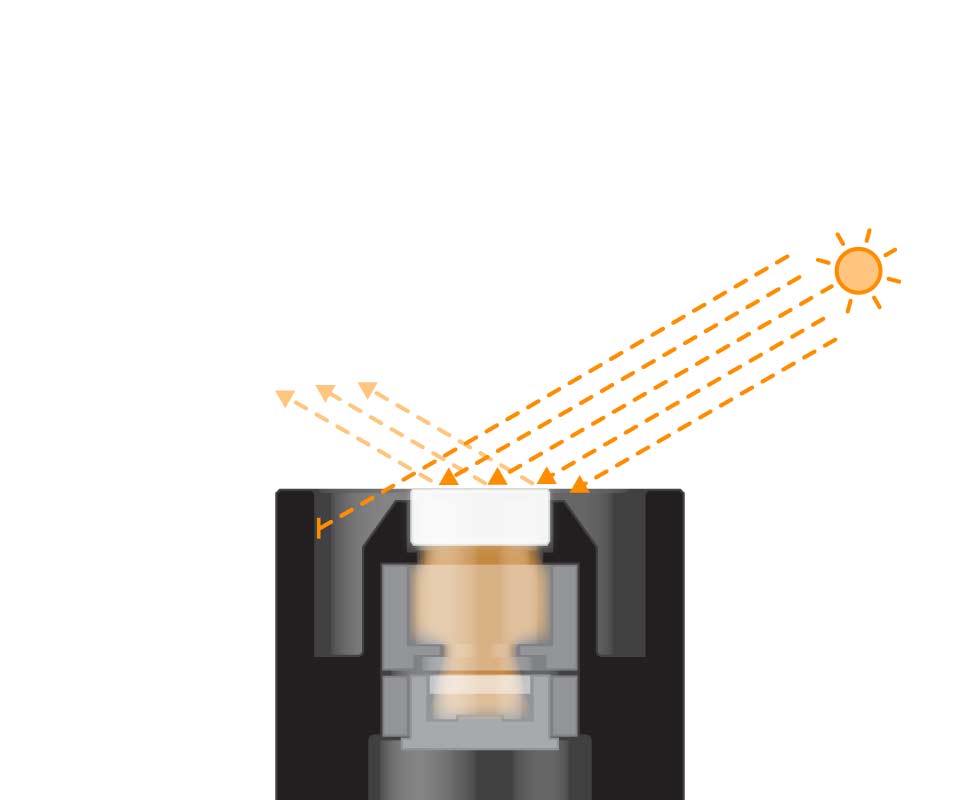

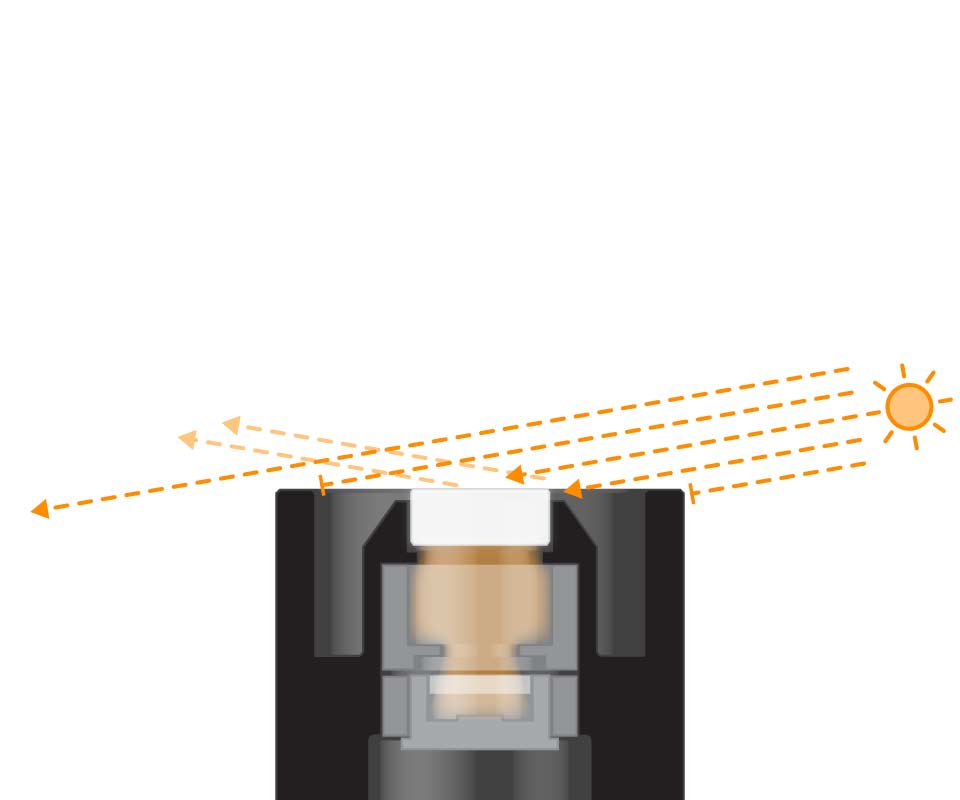

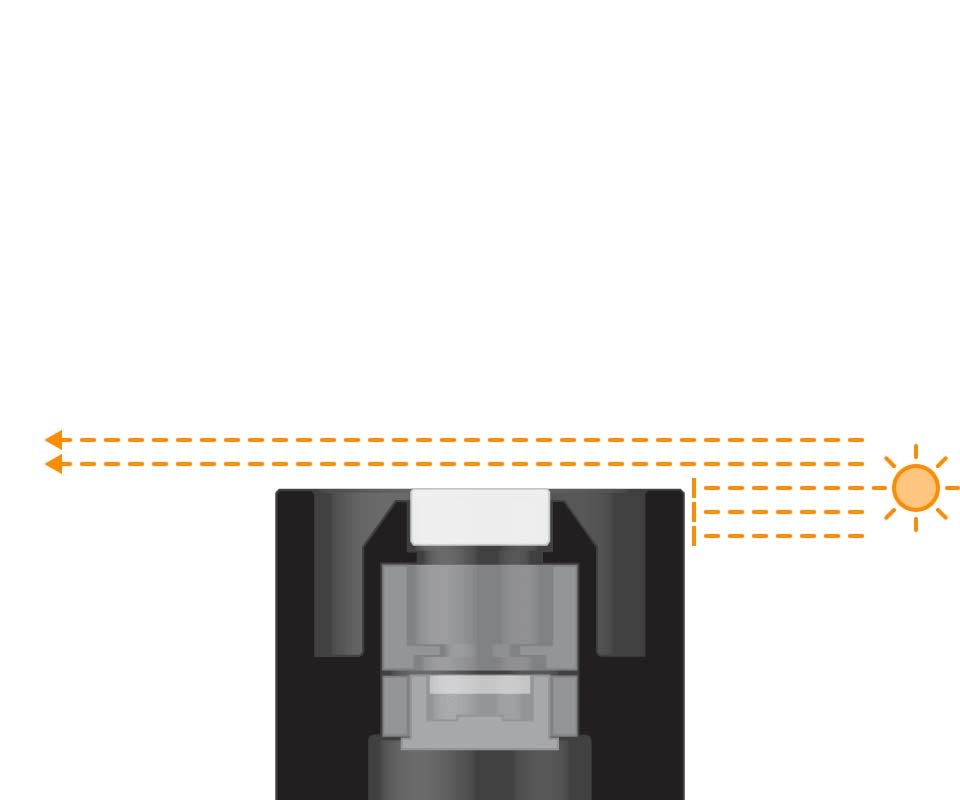

LI-COR terrestrial light sensors are cosine-corrected, following Lambert's cosine law. A cosine-corrected sensor provides the most accurate measurements of radiation on a flat surface from all angles. Cosine correction ensures accurate measurements under various conditions such as low light levels and low solar elevation angles. Accuracy in low light conditions is important for applications such as determining the light compensation point for plants.

The design of the sensor creates the proper cosine response at angles of incidence up to 82°. Radiation is received by an acrylic disc called a diffuser, or ‘eye’. When radiation strikes with a greater angle of incidence, more is received by the edge of the diffuser. This compensates for increasing reflection from the top surface as the angle of incidence grows larger. Beyond an angle of about 80°, the rim of the sensor housing begins to block some radiation, in order to maintain the correct response as more radiation is received by the edge of the diffuser. At a 90° angle of incidence, the rim completely blocks the diffuser, in keeping with a proper cosine response.

Water ingress is one of the most challenging problems confronting environmental sensors. LI-COR sensors feature a large drain, which prevents water from pooling around the sensor element. This increases the lifespan of the sensor and reduces drift in the measurements.

Drag the slider to change the angle of incidence.

Units of Light Measurement

The International System of Units (SI) standard for radiant energy flux is the watt (W). The LI-200R Pyranometer is calibrated to provide units of watts per meter squared (W m-2).

For measurements of photosynthetically active radiation (PAR), we use Photosynthetic Photon Flux Density (PPFD), which is the number of photons in the 400 nm to 700 nm waveband incident per unit time per unit surface area, typically expressed as micromoles of photons per meter squared per second (µmol s-1 m-2).

Photometry is the measurement of visible light with a sensor having a spectral response equal to a typical human eye. Photometry is used to describe lighting conditions where the eye is the primary sensor, such as illumination of work areas, interior lighting, and television brightness. Photometric units are typically presented as illuminance, which is the density of luminous flux incident at a point. Units are typically lux, or lumens per m2.

LI-COR Calibration Standards

Calibration is an integral step in the manufacture of all LI-COR optical radiation-measuring instruments. LI-COR light sensors are designed to provide data in standardized measurement units.

Because of the normal variation in internal optical components, it is necessary to characterize each individual sensor before it leaves LI-COR. This calibration data is supplied as a “calibration constant,” which indicates the amount of sensor output for a given amount of measurable energy input.

Calibration constants are used to convert the raw signal into the appropriate units of solar radiation. A readout device such as the LI-1500 Light Sensor Logger or LI-250A Light Meter can store calibration constants to do this conversion automatically. Other loggers and meters must have their data scaled by a factor determined from the calibration constant to derive the appropriate units.

The characteristics of the optical components may be affected by environmental conditions. We recommend recalibration every two years to ensure correct measurements. Contact LI-COR (envsupport@licor.com) for a return materials authorization (RMA) number prior to returning any instruments.

Pyranometer Calibration

LI-200R Pyranometers are calibrated against an Eppley® Precision Spectral Pyranometer (PSP) under natural daylight conditions. Calibration uncertainty under these conditions is estimated as ± 3% typical, within ± 60° angle of incidence.*

*Preliminary specification

Quantum Sensor Calibration

Quantum sensors, including the LI-190R, LI-191R, LI-192, and LI-193, are calibrated using working standard quartz halogen lamps, which have been calibrated against reference standard lamps traceable to the U.S. National Institute of Standards and Technology (NIST). The absolute calibration specification for quantum sensors is ±5% (typically ±3%) traceable to NIST.

Photometric Sensor Calibration

The LI-210R Photometric Sensors are calibrated using 683 lumens per watt as a value of spectral luminous efficiency at a wavelength of 555 nm ½ power bandwidth. This value conforms to the recommendations of the International Committee for Weights and Measures (CIPM). Calibration is performed using working standard quartz halogen lamps, which have been calibrated against reference standard lamps traceable to the NIST.

Sources of Errors in Light Measurements

Absolute Calibration Errors

Absolute calibration errors depend on the accuracy of the filament-to-sensor distance, alignment accuracy, stray light, the lamp current measurement accuracy, and the accuracy of the transfer function at the time of calibration. Where it is necessary to use a transfer sensor (such as for LI-200R calibrations), additional error will be introduced.

Spectral Response Errors

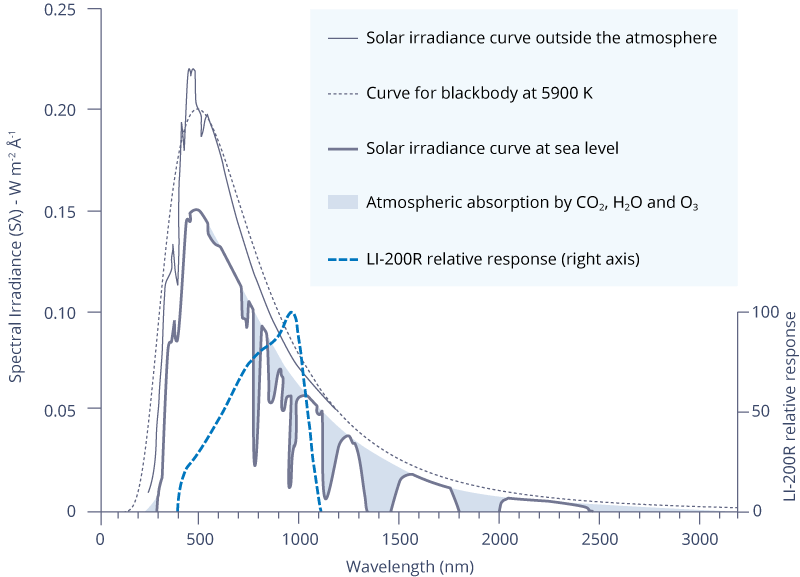

This error is also called actinity error, or spectral correction error. It occurs when the spectra response of the sensor does not conform to the ideal spectral response at a given wavelength. This error occurs when measuring radiation from any source that is spectrally different than the calibration source.

Spectral conformity of LI-COR quantum and photometric sensors is checked with a monochrometer and calibrated silicon photodiode.

An ideal pyranometer is equally sensitive to solar radiation from 280 nm to 2800 nm. The LI-200R is not spectrally ideal. Therefore, it should only be used under natural, unobstructed daylight conditions. Test results show that for clear, unobstructed daylight condition, the LI-COR pyranometer compares very well with class-one thermopile pyranometers2.

Other Errors

Additional errors arise from differences in sensitivity to radiation from different incident angles, tilt, sensor orientation, drift, and other sources.

LI-COR sensors are carefully designed and tested to minimize these errors, and when used as directed, they will present dependable and consistent results.

References

- Kondratyev, K. Ya. 1969. Direct solar radiation. In: Radiation in the atmosphere. Academic Press, New York, London.

- Flowers, E. C. 1978. Comparison of solar radiation sensors from various manufacturers. In: 1978 annual report from NOAA to the DOE.